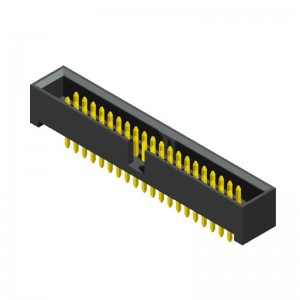

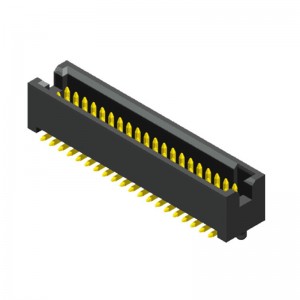

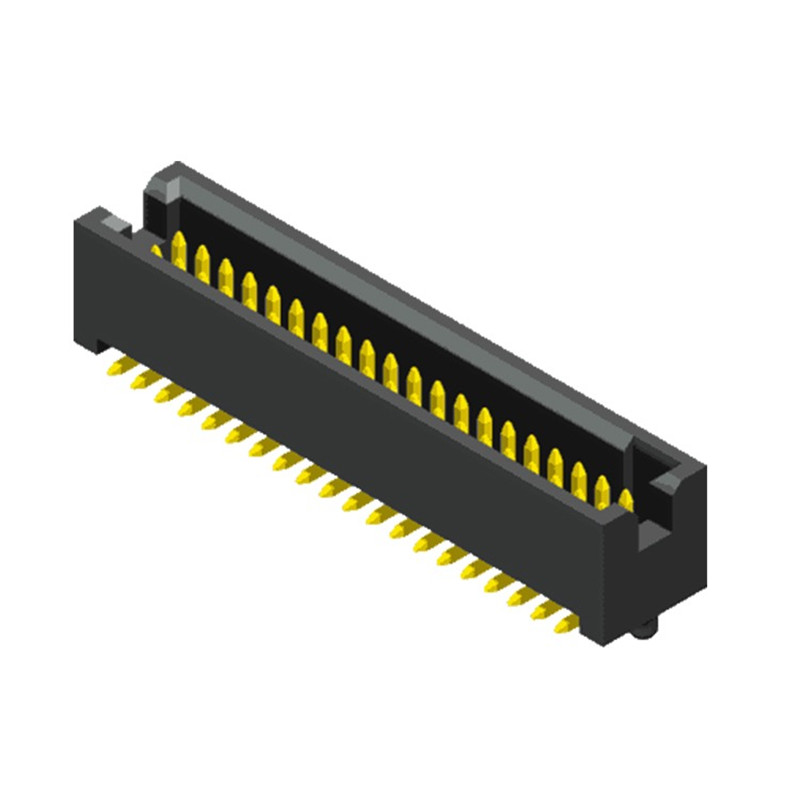

Pin Header Connector _ 1.27mm Pitch Shrouded Idc Ejector Header Connector

Specifications

1, Dielectric Withstanding Voltage: 500V AC/DC

2, Insulation Resistance: 1000 Megohms Minimum.

3, Contact Resistance: 20mΩ Max

Material

1. Housing: LCP.Nylon or PBT (94V-0), color: Black

2. Contact: Copper alloy gold plating over nickel

| Name | Pin header |

| Spacing | 2.54mm |

| Lower board type | SMT |

| Color | Black |

| Plastic material | PA6T |

| Direction | Vertical |

| Rows | 1 |

| Total frequency | 10 |

| Packing | Capped package |

| Operating temperature | -40℃ to +105℃ |

| Rated current | 3.0A |

| Withstand voltage | 500V AC/minute |

A pin header (or simply header) is a form of electrical connector. A male pin header consists of one or more rows of metal pins molded into a plastic base, often 2.54 mm (0.1 in) apart, though available in many spacings.Male pin headers are cost-effective due to their simplicity. The female counterparts are sometimes known as female socket headers, though there are numerous naming variations of male and female connectors. Historically, headers have sometimes been called "Berg connectors", but headers are manufactured by many companies.

Header types can be categorized by their pitch (uniform distance between pins measured from center to center). Some common header pitches are:

5.08 mm (0.200 in)

3.96 mm (0.156 in)

2.54 mm (0.100 in) with 0.64 mm (0.025 in) square pins or precision machined 0.50 mm (0.020 in) round pins

2.00 mm (0.079 in) with 0.50 mm (0.020 in) square pins

1.27 mm (0.050 in)

1.00 mm (0.0394 in)

Order and Mass Production

(1) We will send PROFORMA INVOICE to you when the order is confirmed.

(2) We will start to have mass production when confirming our sample and 30% T/T deposit received.

(3) Customers need to confirm before formal production, we will actively cooperate.

(4) Production and processing in strict accordance with customer requirements (customers can provide samples or drawings).

(5) If the products need to be packed, we can provide our factory's packaging, we can also pack according to the requirements of customers.

(6) We can produce according to some special needs of customers, such as tail processing; labeling; or customers provide materials for us to process injection molding, etc.

(7) Quality is under strict manage and supervision during every production.