Manufacturer of Cinch Terminal Strip - Sheet Metal Progressive Stamping Parts, Electrical Connector Terminals – Weiting

Manufacturer of Cinch Terminal Strip - Sheet Metal Progressive Stamping Parts, Electrical Connector Terminals – Weiting Detail:

Product Description

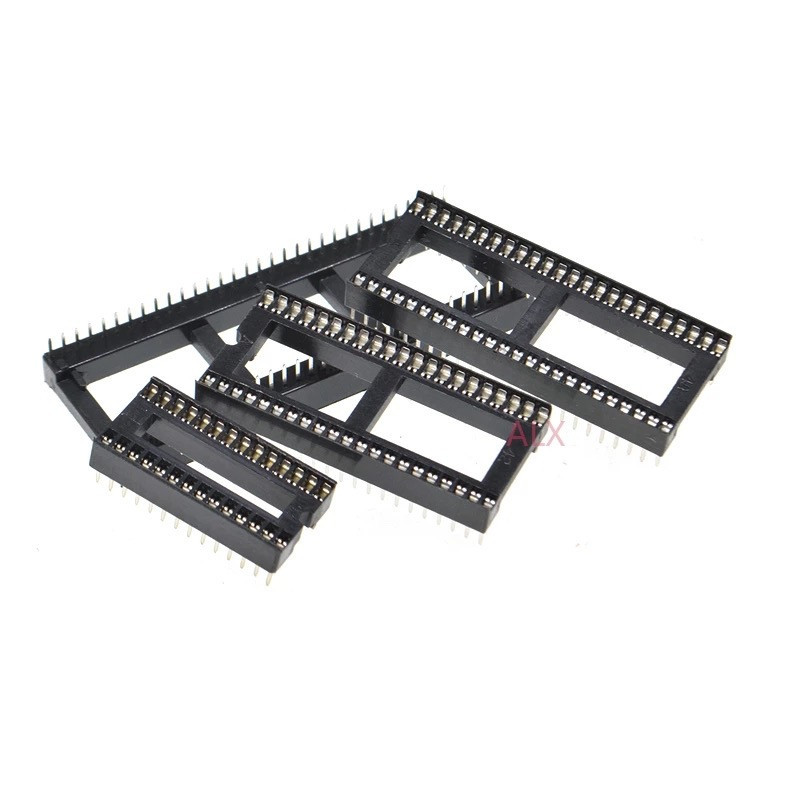

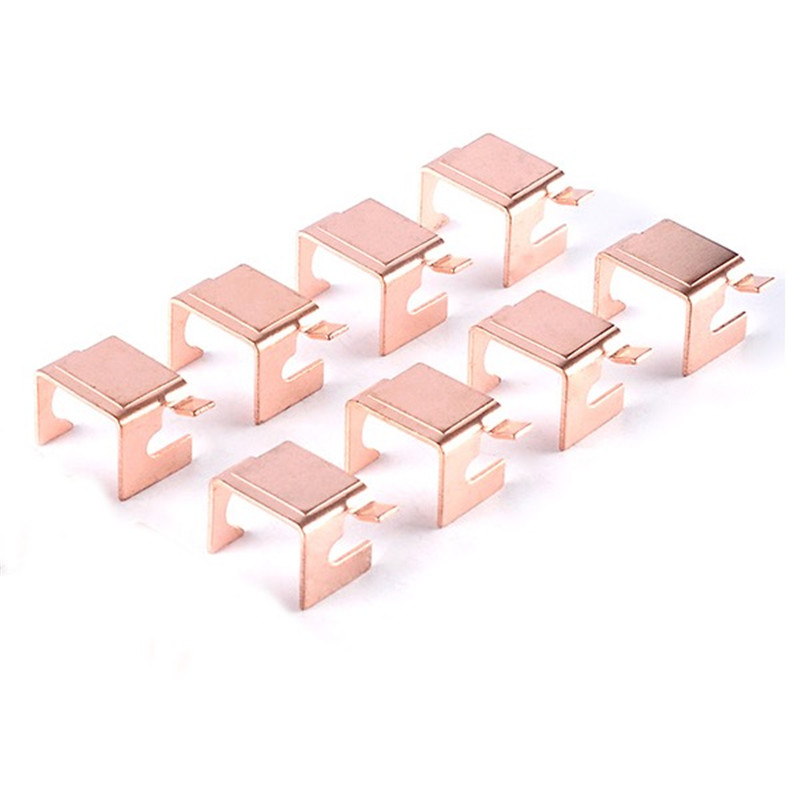

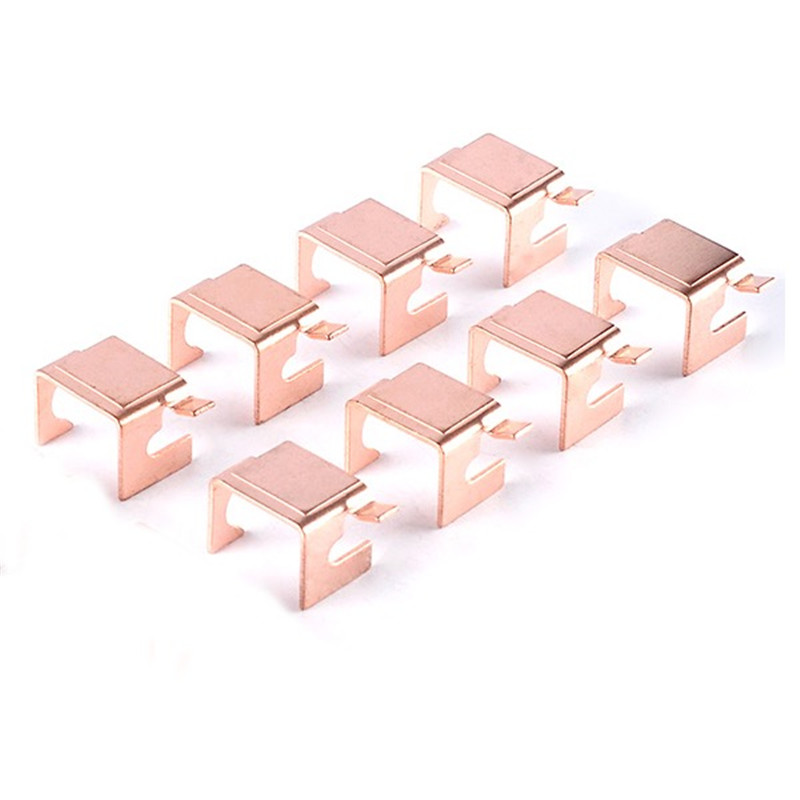

| Product Name | Sheet Metal Progressive Stamping Parts, Electrical Connector Terminals |

| Material | Brass, Copper, Stainless Steel, Aluminum Alloy, Mild Steel, SPCC, SGCC, SECC |

| Process | Laser Cutting, Rivetting, Stamping, Welding |

| Technology | Over 12 Years’ Experience |

| Surface Treatment | Galvanized, Plated, Polishing, Heat-treatment, Wet Painting, Laser Etching, ScreenPrinting, Powder Coating, Anodizing, Passivation |

| Application | Telecom Parts, Automotive, Medical Equipment/Device, Home Appliance, SwitchPower Supply, Furniture |

| Main Products | Sheet Metal (Laser Cutting) Parts, Metal Stamping Bracket, Deep Drawing Parts,Metal Spring Clips, Precision Terminals, CNC Milling and Turning Parts, AluminumCasting Parts |

| Packaging | PE Film, Reel Packaging, Blister Box, Foam, Export Carton etc, or according to thecustomer’s requirement |

Why Choose Us

1:Strict Quality Management System

2.1 Wuntek is ISO9001 certified. We follow up the instruction strictly throughout the whole production process to achieve the highest quality for our customers.

2: 100% inspection

3.1 100% inspection by QC team members to make sure all the products shipped to the customers is qualified

3: One-Stop Solution

4.1 Wuntek offers one stop solution service for metal products because we could provide kinds of manufacturing service include sheet metal (laser cutting) and bending, metal stamping, CNC milling and turning, casting and surface treatment include electroplating, anodizing, powder coating, wet painting, passivation and PVD

4: Strict NDA Policy

5.1 NDA (Non-disclosure Agreement) is signed to ensure customer’s confidential information is inaccessible to outside.

Metal Stamped Parts & Components

We stamp metal parts ranging from small precision parts, such as electronic equipment and musical instruments, to large precision components, including processing equipment and architectural components that are decorative and functional. All-New Stamping has the capability to work in quantities from prototype runs to full production runs.

Our stock thickness for our ferrous and non-ferrous metals ranges from 0.01mm to 2mm and the stock width ranges from 10mm to 1000mm with pre-plated and finishing options. We also work with a complete range of materials to offer customers a large choice in specifications, including:

Welcome to plans to sample, a model can be designed

Product detail pictures:

Related Product Guide:

We always do the job to be a tangible group making sure that we can provide you with the top top quality as well as ideal value for Manufacturer of Cinch Terminal Strip - Sheet Metal Progressive Stamping Parts, Electrical Connector Terminals – Weiting , The product will supply to all over the world, such as: Saudi Arabia, Honduras, Chicago, We've got more than 10 years experience of production and export business. We always develop and design kinds of novel items to meet the market demand and help the guests continuously by updating our goods. We've been specialized manufacturer and exporter in China. Wherever you are, make sure you join us, and together we will shape a bright future in your business field!

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.